Production Center

Mold:

? ? The mold department has advanced processing equipment (MORISEIKI,+GF+, Makino, Beijing Jingdiao, etc.) and testing equipment. The mold processing accuracy can reach 0.005mm, and the new mold production cycle is within 15 days. By importing PLM and mold MES system management, the mold manufacturing is standardized and modularized。

Injection molding:

? ? Each injection molding machine and more than ten auxiliary automation equipment have been integrated to achieve modular flexible production. By combining the injection molding MES system, the injection molding production process and related parameter monitoring are more stable, and the products produced are perfect。

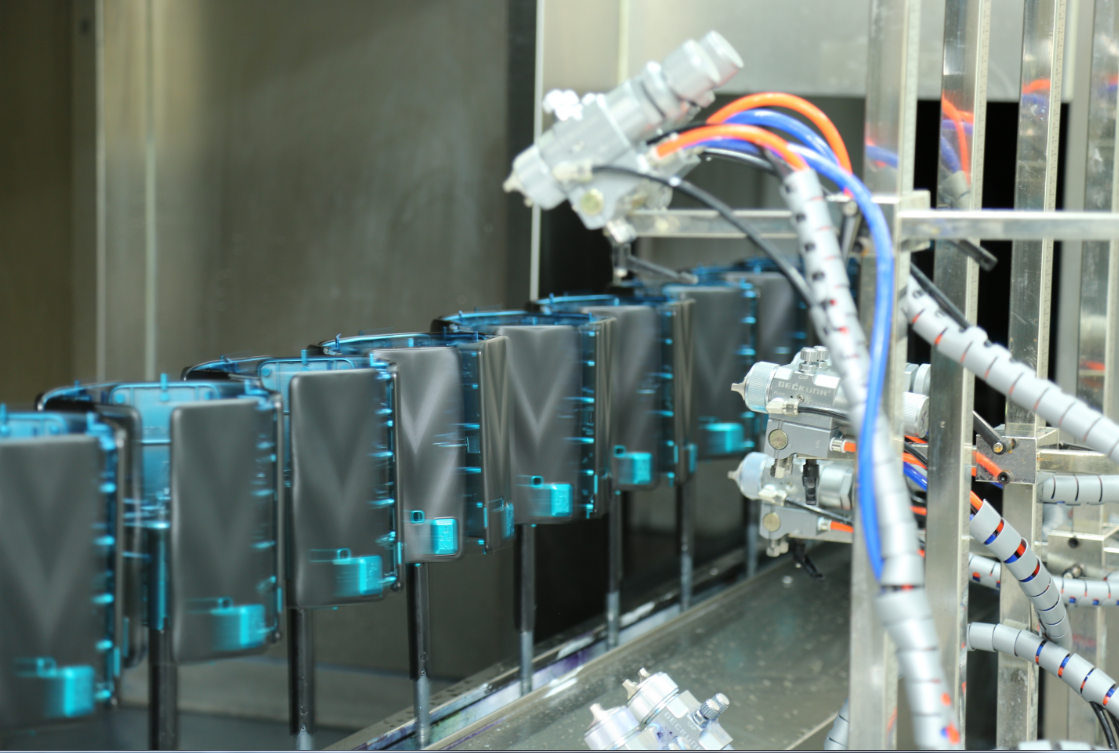

Spraying/Vacuum Plating/Optical Plating/Screen Printing/Environmental Protection:

? ? Spraying, vacuum plating, optical plating, laser engraving and other production processes are closely combined to provide customers with the most cutting-edge appearance innovation。In order to better protect the environment, an intelligent automatic line integrating spraying equipment and environmental protection equipment was developed in 2020. Vigorously invest in environmental protection teams, laboratories, and equipment to ensure zero wastewater discharge and exhaust emissions meeting the strict environmental standards of Dongguan City。

Carving workshop:

The precision carving workshop is equipped with an assembly line operation of robots, combined with an MES system, to provide precise and efficient product processing services。

assemble:

? ? The assembly workshop is fully automatic in fitting auxiliary materials, combined with the MES system to achieve intelligent and less manual assembly. Assemble plastic parts, metal parts, antennas, auxiliary materials, glass ceramics, etc. into a complete set of components。